Project Case

With the rapidly development of Industrial Ethernet technology, production enterprises from the initial distributed automation management system turn to intelligent, visual, digital and real-time control of the development. Enterprises need a solution that integrates an open Industrial Ethernet infrastructure with overall real-time Communications. This product can meet the requirement of industrial control field for unified communication protocol and real-time communication, it can achieve the effect of data exchange, meet the needs of enterprises and also more efficient and efficient to users.

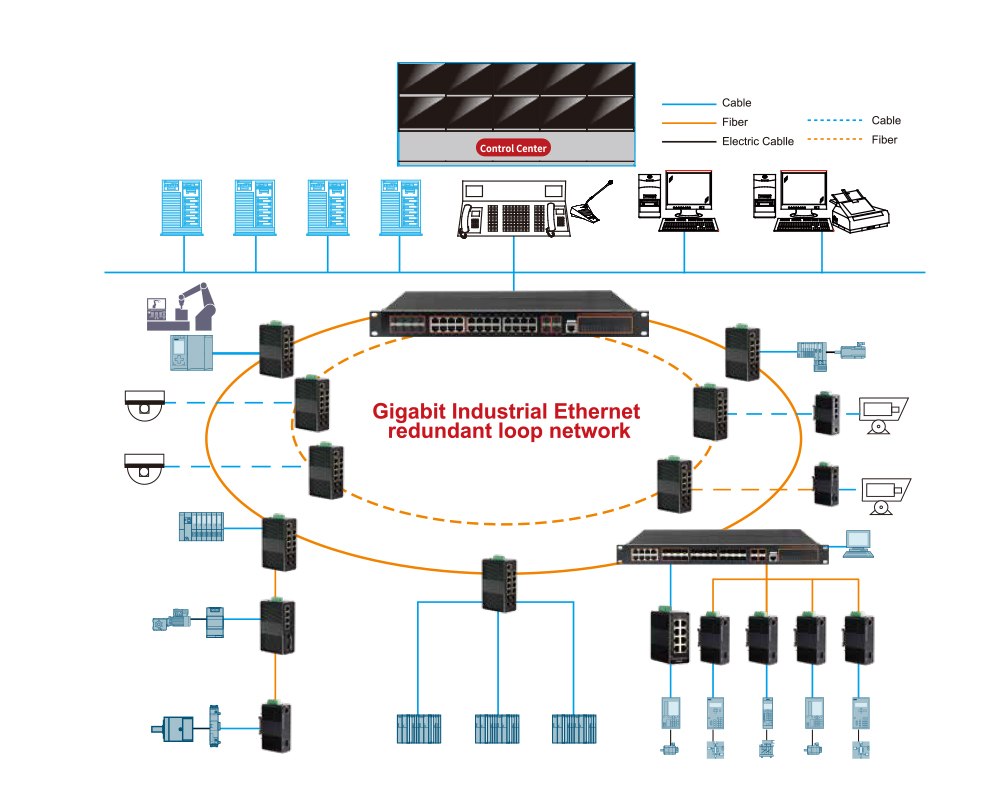

The industrial environment requires high reliability of industrial control network and strong redundancy function of industrial Ethernet; the industrial control requires high real-time communication. The industrial environment is extremely harsh and often requires industrial Ethernet equipment to run in the environment with strong electromagnetic interference, severe vibration, dust, ultra-high temperature or ultra-low temperature for a long time. Our self-developed Gigabit-managed series industrial Ethernet switches are designed for harsh industrial environments and have reliable redundancy features, making them the ideal choice for industrial control communications.

The network scheme uses NEU50244T8CGS-SFP core layer Industrial Ethernet switches as the backbone network from the control center to connect with NEU3084GM-SFP L2 management ring switches in each workshop to form a gigabit fiber link redundant self-healing ring network, at the same time, the control information of the control station is transmitted to many automatic equipments, such as PLC, to realize the unified management and automation of automatic equipments and sensor equippments.

CATEGORIES

- The Case Of Auxiliary Control System Of A Power Plant

- The case of a factory automation control system

- The case of video surveillance in a highway tunnel

- The case of automatic fire protection system of a wind generator

- The case of video surveillance of a river water environment

- The case of smart street lamp control system

LATEST NEWS

CONTACT US

Contact: Kevin

Phone: 13713382963

Tel: 13713382963

Email: info@three-link.com

Add: Third Floor, Building 1, No.75 Jianshe Road, Qishi Town, Dongguan City